Dupa plasarea solicitării de comandă, in sectiunea Istoric puteti vedea cate solicitări de comandă mai avem de procesat inaintea dumneavoastra

Program de lucru: Luni - Vineri 9:00 - 18:00, pauza 13:00 - 14:00.

Se efectueaza lucrari de mentenanta la site si pot aparea erori. In cazul in care intampinati erori va rugam sa reincercati mai tarziu.

Ridicarea personala este disponibila pentru comenzile achitate in avans. Se pot ridica dupa ce sunt pregatite.

Coş

0

Produs

Produse

(gol)

Niciun produs

Urmeaza a se stabili

Livrare

$0.00

Total

Produs adăugat cu succes la coşul dvs.

Cantitate

Total

0 articole în coșul dvs.

Aveţi un produs în coş.

Total produse:

Total livrare

Urmeaza a se stabili

Total

Reduceri!

Mărește

Mărește

Mărește

Mărește

Imaginile sunt utilizate exclusiv cu titlu de prezentare. Fotografiile nu creează obligații contractuale.

Filament FormFutura Volcano PLA - Negru, 1.75 mm, 2.3 kg

8718924479087

Produs nou

Filament FormFutura Volcano PLA - Negru, 1.75 mm, 2.3 kg

Acest produs nu mai este in stoc

- Scrie o recenzie

- Elimina acest produs din lista mea de favorite.

- Adauga acest produs la lista mea de favorite.

- Imprimă

Informații

Filament FormFutura Volcano PLA - Negru, 1.75 mm, 2.3 kg

Recenzii

Clienții care au cumpărat acest produs au mai cumpărat:

-

FormFutura...

FormFutura FlexiFil Filament - Black, 1.75 mm,...

$23.73

-

Magnet...

Magnet Paralelipipedic din Neodim 8x4x1 mm N38

$0.29

-

Rulment...

Rulment Liniar LM8UU

$0.97

-

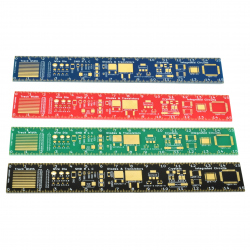

Riglă Roșie...

Riglă Roșie cu Capsule de Componente...

$1.92

-

Roată pentru...

Roată pentru Feederul de Filament de la...

$1.00