Dupa plasarea solicitării de comandă, in sectiunea Istoric puteti vedea cate solicitări de comandă mai avem de procesat inaintea dumneavoastra

Program de lucru: Luni - Vineri 9:00 - 18:00, pauza 13:00 - 14:00.

Se efectueaza lucrari de mentenanta la site si pot aparea erori. In cazul in care intampinati erori va rugam sa reincercati mai tarziu.

Ridicarea personala este disponibila pentru comenzile achitate in avans. Se pot ridica dupa ce sunt pregatite.

No products

View larger

View larger

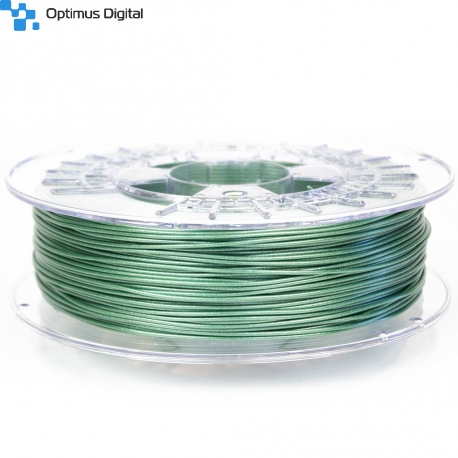

ColorFabb nGen_Lux Filament - Nature Green 750 g 1.75 mm

8719033556461

New product

Green means positive. Green means life. Green means nature. Bring an extraordinary and unique look to your creations. This shade of green is a mix of the most amazing emerald green and a decent amount of what looks like fairy dust.

See description for more details about the product.

Add to cart now!

1 Item

Warning: Last items in stock!

- Write a review

- Remove this product from my favorite's list.

- Add this product to my list of favorites.

More info

Description

nGen_LUX is a unique development based on our best-selling co-polyester nGen, made with Eastman Amphora AM3300 3d Polymer. The excellent clarity of the base AM3300 makes this material uniquely suited for the extremely rare pigment used in nGen_LUX. The material uses diffuse reflection to scatter light in all directions.

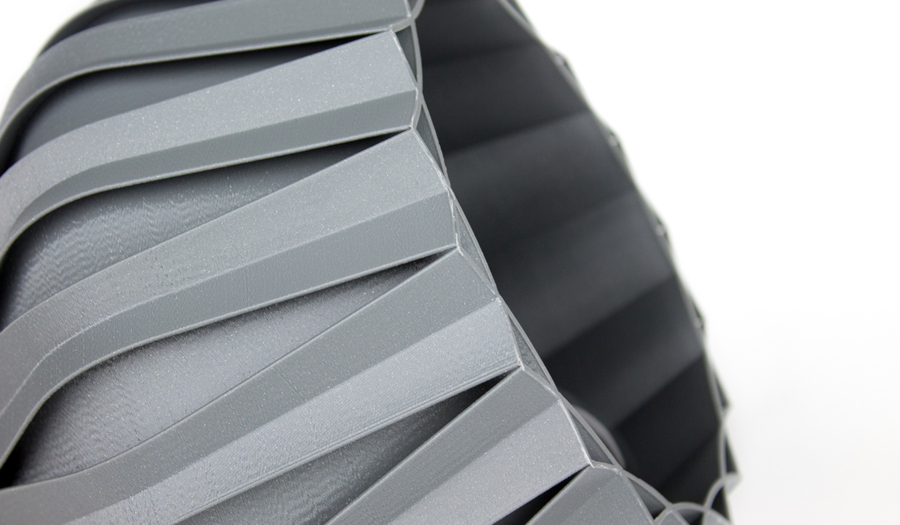

For the eye, it’s nearly impossible to spot layering, even at 0.2mm layer height. nGen_LUX allows users to print visually appealing models without the need for post-processing. nGen_LUX features all the characteristics of our regular nGen, good chemical stability, elevated temperature resistance (85°C) and thus allows users to print creations that are functional, durable, efficient and attractive.

What makes nGen?

nGen is made from Eastman Amphora™ AM3300 3D polymer. Like colorFabb_XT, it is part of Eastman’s Amphora range of copolyesters for 3D printing.

nGen is a low-odor, styrene-free material uniquely suited for 3D printing enthusiasts, particularly those who need the flexibility to print within a wide processing temperature range. With nGen you will have good flow properties through the printer nozzle—even at lower temperatures than some other polymers require. These properties make nGen more workable at a wider breadth of temperatures, producing reliable results and resulting in less waste.

With the unique combination of low processing temperature and elevated temperature resistance, nGen can quickly print creations that are functional, durable, efficient, and attractive.

Why nGen?

3D printing nowadays has many applications: reprapping, making gadgets, prototyping, designing, impressing people, having fun or making serious money. Whatever you do with your printer, the material should suit your needs. Sometimes your print needs to look beautiful, other times it needs to be functional. But what if you can use the same roll of filament?

With nGen we bring a filament to the market that has functional properties, looks astonishingly good and prints like a dream. With a glass temperature of over 85ºC, it has over double the heat resistance of PLA.

Hydrolitical stability

One of nGen truly unique features is its melt stability, meaning from pellet to filament to 3D Printed part, the mechanical properties of the material will hardly be affected. This provides a great deal of printing stability and the ability to reproduce the same quality parts over and over again, reducing failed prints rates.

Applications for nGen

You might be wondering who should be using nGen and to answer that question we’ve highlighted various areas of application below. We think each of these areas will benefit greatly from the specific material characteristics of colorFabb nGen. Find out below which characteristic makes nGen a good match

Home Appliances

This is definitely a very popular category amongst many early adopters of 3D printers. For the most part, we need the material to remain stable over a long-term and keep its mechanical performance.

nGen is uniquely suited because of its durable nature and good heat resistance.

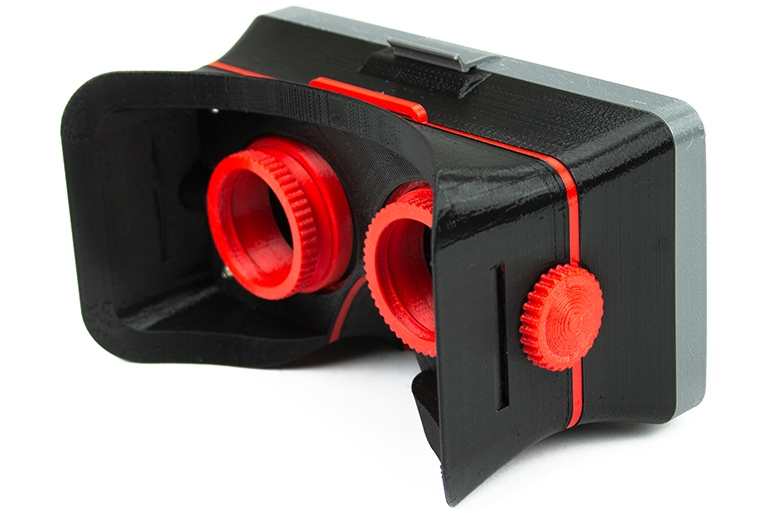

Consumer Electronics

We expect many more applications to be developed in this area. Whether it’s a headphone or housing for holding electronics parts the material needs good stability and decent heat resistance. Of course, colors are important too, especially when these electronics are custom made to your liking.

Toys

For toys, we need materials with great colors and good stable mechanical properties. nGen comes in 17 colors and we will add more colors in the coming months. Because of nGen’s good mechanical properties, parts will last a long time.

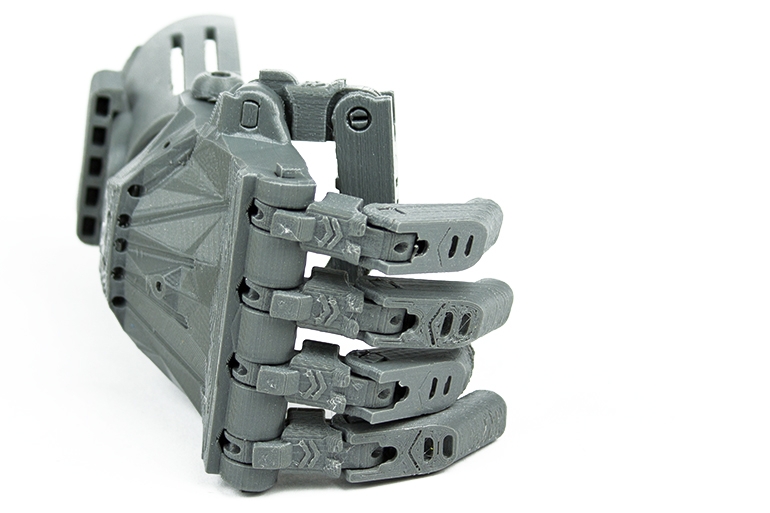

Visual & Functional Prototyping

Prototyping is a great tool for designers and companies to get a feel for their concepts & ideas early on in the development. However, ideally, we want to use these prototypes not only for visual approval but also subject them to real functional tasks. nGen material is well suited for this job with a high TG of 85C and a very durable nature which retains mechanical performance over time.

Modeling / Character design

Printing high resolution is no problem with nGen. With good performance on overhanging surfaces and great stability during print, we think this makes nGen a good partner for character designers wanting to 3D print their own creations.

Lighting

It’s a lot of fun to create your own lighting designs for home or office use. However, the material needed for such applications need heat resistance and should remain stable over time. nGen’s properties tie in very well with 3D printing custom lighting which will last.

Medical

Durable materials will be well suited for Medical applications. There’s no point in printing prosthesis with biobased filaments as they will lose mechanical properties over time. Instead, long term stability is needed which nGen is perfect for. Cleaning nGen is no problem because of its excellent chemical resistance.

How to print with nGen

To get the best possible quality out of any 3D printing material it’s important to match the slicer settings with the material which is used. On this page, we’ll run through the most important settings and suggest good starting values for various printers. If your machine isn’t in our list use the general recommended settings.

In the table below you can quickly find values for your machine, scroll a bit further down to read more about each setting.

Print Settings

| ULTIMAKER 2 (CURA) | MP PHARAOH ED (SIMPLIFY3D) | MP PHARAOH ED (SIMPLIFY3D) | LULZBOT MINI (CURA) | STACKER (SIMPLIFY3D) | |

|---|---|---|---|---|---|

| Print temperature | 220°C/240°C | 220°C/240°C | 220°C/240°C | 220°C/240°C | 230°C/250°C |

| Build platform temperature | 75°C/85°C | 75°C/85°C | 75°C/85°C | 75°C/85°C | 75°C/85°C |

| Print speed | 40/60 mm/s | 40/60 mm/s | 50/70 mm/s | 40/60 mm/s | 40/60 mm/s |

| Cooling | 50% | 50% | 50% | 50% | 50% |

| Retraction – speed | 45 mm/s | 45 mm/s | 45 mm/s | 10/25 mm/s | 60 mm/s |

| Retraction – length | 4.5 mm | 4.5 mm | 3.2 mm | 1.0/2.0 mm | 3.7 mm |

| Bridge – speed | n.a. | n.a. | 50/80% | n.a. | 50% |

| Bridge – cooling | n.a. | n.a. | 100% | n.a. | 100% |

| Bridge – flow | n.a. | n.a. | 110% /120% | 110% /120% | 110% /120% |

Heated platform

nGen is best printed on a heated build platform. You want to be near the heat resistance temperature of 85C. Therefore most 3D printers will do fine with 75C/85C platform temperature.

If your machine doesn’t feature a heated platform, then you can look into using accessories such as BuildTak, 3Deeze and 3DLac. For small to medium-sized parts the accessories can work, but for large parts covering the entire build platform, it most likely will show warping on the bottom of the print.

Printing temperature

The temperature we set when starting a print really depends on the chosen layer height and print speed.

Flow of material in mm3/s = (layerheight*nozzle width)*print speed

When considering normal settings such as 0.2mm layer height and 50 mm/s speed we recommend for most machines a processing temperature of 220C / 240C.

When settings are much different than a regular setup, for instance, 0.05mm and 50 mm/s print speed the set temperature could be adjusted. In this case, it’s likely that you won’t need as high temperature as in Case 1, because the mm/3 s is 4x less.

Cooling

nGen is a highly efficient material, with elevated glass temperature of 85C but a processing temperature of 220C/240C meaning less heat to dissipate to cool down below glass temperature. It performs great on overhangs, as long as they are still attached to the main model.

If you’re used to setting a 100% fan speed all the time, you might want to experiment with less cooling if you notice layer adhesion or part strength could be better. If a layer cools down too much it will adhere less to the next layer.

We also like the option of only activating layer cooling for the perimeter lines, the infill is not cooled and therefore should maintain the best possible layer.

Bridging

Most slicers will allow users to set special settings when a bridge is printed in a model. Usually, we can set bridging speed, bridging cooling and sometimes also bridging perimeter width (or flow).

We recommend slower printing on bridges since there’s no material to support the printed line we don’t want to ‘break the melt’ by moving too fast. Slowing down the speed when bridging helps retain the melt strength and also allows the printed line to cool down in mid-air.

Cooling can be set at 100% to help the cooldown of the first printed lines.

If you can still see the melt break when printing a bridge, try and increase the flow or bridge perimeter width.

Retraction

Before you start tweaking the retraction values make sure you’ve found the sweet spot in terms of printing temperature and speed for your machine.

PLA retraction values should be a good starting value for most machines. One can expect slightly higher values of retraction speed and retraction length.

Coasting is a nice option included in Simplify. This is the act of stopping the extrusion just before a travel move is triggered, this helps get rid of the pressure in the hot-end and therefore also making a retraction move more effective.

We also like the option of only activating layer cooling for the perimeter lines, the infill is not cooled and therefore should maintain the best possible layer adhesion.

Minimal layer time

If you’re familiar with the minimal layer time setting then you’ll know this is what causes a printer to slow down when printing fine features on a model. Slowing down the print allows each layer to cool down a minimum amount of time. This is, of course, different for each material, because it depends on how fast a material can dissipate heat and how much heat needs to be dissipated.

For nGen we reckon you should be able to lower this value compared to your standard PLA value. How much exactly is hard to tell as it depends on the printers cooling efficiency.

Don't delay. Buy today.

Add to cart now!

Reviews

Customers who bought this product also bought:

-

1.75 mm, 1...

You can easily print with this PLA filament and...

$16.80

-

2x4 mm...

2 x 4 mm Teflon Tube

$2.64

-

1.75 mm, 1...

You can easily print with this PLA filament and...

$16.80

-

1.75 mm, 1...

You can easily print with this PLA filament and...

$19.20

-

1.75 mm, 1...

You can easily print with this PLA filament and...

$16.80

-

1.75 mm, 1...

You can easily print with this PLA filament and...

$19.20