Dupa plasarea solicitării de comandă, in sectiunea Istoric puteti vedea cate solicitări de comandă mai avem de procesat inaintea dumneavoastra

Program de lucru: Luni - Vineri 9:00 - 18:00, pauza 13:00 - 14:00.

Se efectueaza lucrari de mentenanta la site si pot aparea erori. In cazul in care intampinati erori va rugam sa reincercati mai tarziu.

Ridicarea personala este disponibila pentru comenzile achitate in avans. Se pot ridica dupa ce sunt pregatite.

Niciun produs

Mărește

Mărește

Filament nGen ColorFabb 1.75 mm 750 g - Verde Inchis

8719033554061

Produs nou

nGen este usor de utilizat, chiar si la temperaturi scazute, fata de ceilalti polimeri. Astfel se poate lucra la o gama mai larga de temperaturi, ceea ce rezulta in mai putin filament irosit si mai multe proiecte reusite.

2 bucati in stoc

Ultimele bucăți în stoc

- Scrie o recenzie

- Elimina acest produs din lista mea de favorite.

- Adauga acest produs la lista mea de favorite.

- Imprimă

Informații

colorFabb has teamed up with Eastman Chemical Company to develop co-polyester based materials for FFF/FDM 3D printing. Now you can fulfill your vision with 3D creations that exhibit sparkling clarity and gloss and superior toughness. With superior melt strength and dimensional stability, Amphora delivers advanced bridging capabilities to create stronger and more detailed items—with low odor and low emissions.

nGen is a low-odor, styrene-free choice that is uniquely suited for 3D printing applications. With Amphora, items can be created that are more functional, more durable, more efficient, and attractive.

nGen is made with Amphora AM3300 and has good flow properties through the printer nozzle - even at lower temperatures than some other polymers require. These properties make nGen more workable at a wider breadth of temperatures, producing reliable results and resulting in less waste. nGen exhibits advanced overhang ability, excellent looks, and large printing temperature range—empowering a large panel of users to create durable and useful items

Key Attributes

- Clarity and Gloss

- Dimension Stability

- Enhanced Aesthetics

- Excellent Toughness and Temperature Resistance

- Extended Processing Window

- FDA Compliance

- Low Odor

- Property Retention in 3D applications

- Styrene-free

- Workability

| Proprietăți Generale | Metoda | Valoare |

|---|---|---|

| Gravitația Specifică | D 792 | 1.20 g/cm3 |

| Properietăți Mecanice | Metoda | Valoare |

|---|---|---|

| Tensile Stress @ Yield | D 638 | 50 MPa (7210 psi) |

| Tensile Stress @ Break | D 638 | 35 MPa (6240 psi) |

| Elongation @ Yield | D 638 | 4.5% |

| Elongation @ Break | D 638 | 193% |

| Modul de elasticitate la îndoire | D 790 | 1800 MPa (2.60 x 105 psi) |

| Rezistența la îndoire | D 790 | 67 MPa (9717 psi) |

| Rockwell Hardness, R Scale | D 785 | 105 |

| Rezistența la șoc Izod | D 256 | 70 J/m (@23°C); 38 J/m (@-40°C) |

| Thermal Properties | Metoda | Valoare |

|---|---|---|

| Deflection Temperature | ||

| @ 0.455 MPa (66 psi) | D 648 | 71°C(160°F) |

| @ 1.82 MPa (264 psi) | D 648 | 63°C(145°F) |

| Typical Processing Conditions | Valoare |

|---|---|

| Processing Melt Temperature | 210-240°C |

| Heated Bed Temperature | 60°C |

| Cooling | 0 to 100% |

| Înălțimea stratului | 0.1 or 0.2 mm |

| Speed | 30 to 100 mm/s |

| Infill | As needed up to 100% |

| Perimeter | Around 1 mm |

| Minimal Layer Time | 4 sec |

Adaugă în coș acum!!

Recenzii

Clienții care au cumpărat acest produs au mai cumpărat:

-

Controller...

Controller PWM de Viteza a Motoarelor

$6.00

-

Curea...

Curea Inchisa 2GT-6-280 mm

$3.48

-

Hub de...

Hub de Cuplaj Flexibil de la 5 mm la 5 mm cu...

$1.44

-

Roata...

Roata Dintata 2GT-20 cu 20 Dinti de 6 mm...

$2.40

-

Filament...

Ingeo 3D870 este un material dezvoltat pentru...

$24.00

-

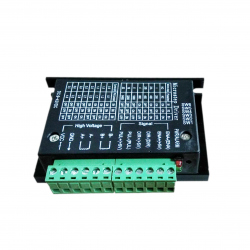

Driver...

Driver pentru motor pas cu pas TB6600 4A 42V

$9.60

-

Termometru...

Termometru digital, de culoare neagră, cu...

$2.88

-

Dispozitiv...

Dispozitiv de Blocare pentru Șuruburi T8

$1.68

-

Rulment...

Rulment 688ZZ (8x16x5 mm)

$0.42

-

Profil...

Profil Argintiu Aluminiu V-Slot 2040 40 cm

$7.20