Dupa plasarea solicitării de comandă, in sectiunea Istoric puteti vedea cate solicitări de comandă mai avem de procesat inaintea dumneavoastra

Program de lucru: Luni - Vineri 9:00 - 18:00, pauza 13:00 - 14:00.

Se efectueaza lucrari de mentenanta la site si pot aparea erori. In cazul in care intampinati erori va rugam sa reincercati mai tarziu.

Ridicarea personala este disponibila pentru comenzile achitate in avans. Se pot ridica dupa ce sunt pregatite.

Niciun produs

Mărește

Mărește

Filament XT ColorFabb 1.75 mm 750 g - Portocaliu

8719033553354

Produs nou

XT este un nou tip de filament pe baza de polimeri de la ColorFabb. Acesta este un material extrem de rezistent, atat mecanic, cat si termic.

1 bucata in stoc

Ultimele bucăți în stoc

- Scrie o recenzie

- Elimina acest produs din lista mea de favorite.

- Adauga acest produs la lista mea de favorite.

- Imprimă

Informații

Filamentele ColorFabb_XT sunt realizate din materiala pe baza de polimeri pentru imprimantele 3D FFF/FDM. Acestea emit putin fum si nu au stiren in compozitie.

Atribute principale:

- Stralucire si claritate

- Stabilitate dimensionala

- Usurinta de procesare

- Rezistenta termica ridicata

- Rezistenta mecanica excelenta

- Respecta normele FDA

- Aproape inodor

- Fara stiren

| Filament | Unitate | Valoare |

| Diametru | mm | 1.75 |

| Deviatie maxima | mm | 0.05 |

| Greutate neta | g | 750 |

| Proprietati fizice | Unitate | Valoare |

| Gravitatie specifica | g/cm3 | 1.27 |

| Proprietati mecanice | Unitate | Valoare |

| Rezistenta la tractiune | MPa | 50 |

| Modul de tractiune | MPa | 1900 |

| Alungirea la rupere | % | 110 |

| Alungire la 50MPa | % | 5 |

| Rezistenta la impact | J/m | 95 |

| Modul de indoire | MPa | 2100 |

| Proprietati termice | Unitate | Valoare |

| Rezistenta termica (dupa printare) | °C | 70 |

| Informatii pentru printare | Unitate de masura | Valoare |

| Temperatura duzei | ºC | 240-260 |

| Temperatura patului incalzit | ºC | 70 |

| Temperatura de recoacere | ºC | 110-120 |

| Viteza ventilatorului* | % | 50-90 |

| Inaltimea stratului | mm | 0.1-0.2 |

| Grosimea invelisului | mm | 1.2 |

| Viteza de printare | mm/s | 30-60 |

*Primii 1-2 cm se recomanda a fi printati cu ventilatorul la o viteza minima/oprit.

Recenzii

Clienții care au cumpărat acest produs au mai cumpărat:

-

Filament...

nGen este usor de utilizat, chiar si la...

$22.56

-

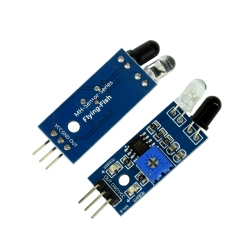

Modul Senzor...

Senzor pentru detectarea obstacolelor, cu...

$0.84

-

Filament XT...

XT este un nou tip de filament pe baza de...

$24.00

-

Filament...

Filamentul PETG Sakata 3D este potrivit pentru...

$27.60