Dupa plasarea solicitării de comandă, in sectiunea Istoric puteti vedea cate solicitări de comandă mai avem de procesat inaintea dumneavoastra

Program de lucru: Luni - Vineri 9:00 - 18:00, pauza 13:00 - 14:00.

Se efectueaza lucrari de mentenanta la site si pot aparea erori. In cazul in care intampinati erori va rugam sa reincercati mai tarziu.

Ridicarea personala este disponibila pentru comenzile achitate in avans. Se pot ridica dupa ce sunt pregatite.

Niciun produs

Mărește

Mărește

Filament Sakata 3D 3D ABS - Arămiu 1.75 mm 1 kg

0104110000071682

Produs nou

Filament Sakata 3D 3D ABS - Arămiu 1.75 mm 1 kg

Acest produs nu mai este in stoc

- Scrie o recenzie

- Elimina acest produs din lista mea de favorite.

- Adauga acest produs la lista mea de favorite.

- Imprimă

Informații

Filament Sakata 3D 3D ABS - Arămiu 1.75 mm 1 kg

Recenzii

Clienții care au cumpărat acest produs au mai cumpărat:

-

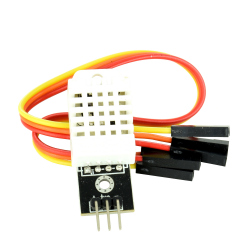

Modul Senzor...

Modul DHT22 este un senzor de temperatura si...

$5.55

-

$2.40

-

Stație de...

Stația de lipit Plusivo este ideală pentru un...

$35.76

-

Tastatura...

Tastură cu 16 butoane cu conectori de tip mamă.

$1.68

-

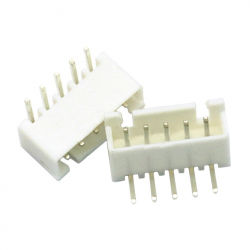

Conector...

Conector Tată Drept XH2.54 3p

$0.12

-

Conector...

Conector Tată XH2.54 la 90° 5p

$0.24

-

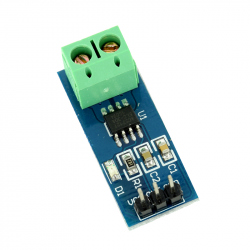

Senzor de...

Acest senzor de curent este unul bidirecțional,...

$3.60

-

Conector...

Conector Tată XH2.54 2p (Negru)

$0.12

-

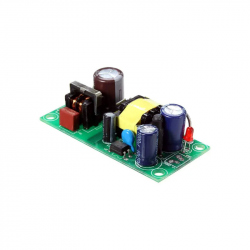

Modul Sursă...

Modul Sursă de Alimentare (220 V către 5 V, 2...

$5.76

-

Șubler...

Șubler Digital Argintiu din Fibra de carbon...

$8.40