Dupa plasarea solicitării de comandă, in sectiunea Istoric puteti vedea cate solicitări de comandă mai avem de procesat inaintea dumneavoastra

Program de lucru: Luni - Vineri 9:00 - 18:00, pauza 13:00 - 14:00.

Se efectueaza lucrari de mentenanta la site si pot aparea erori. In cazul in care intampinati erori va rugam sa reincercati mai tarziu.

Ridicarea personala este disponibila pentru comenzile achitate in avans. Se pot ridica dupa ce sunt pregatite.

No products

View larger

View larger

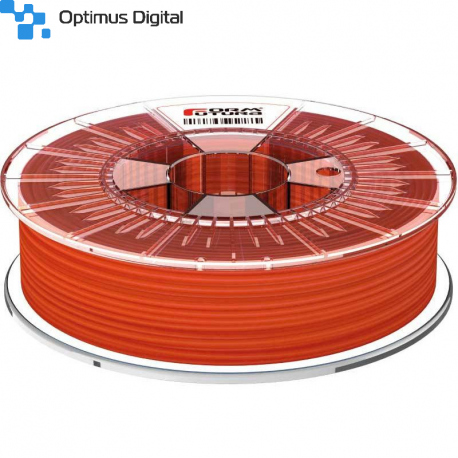

FormFutura TitanX Filament - Red, 2.85 mm, 750 g

8718924476246

New product

TitanX is a high-end engineering filament with ABS (acrylonitrile butadiene styrene) as the main component.

See Description for more details about the product.

Don't delay, buy today. Add to cart now!

1 Item

Warning: Last items in stock!

- Write a review

- Remove this product from my favorite's list.

- Add this product to my list of favorites.

More info

Description

The formulation of TitanX is enhanced with added polymers, binding agents and impact modifiers resulting in an engineering filament that combines exceptional mechanical properties with optimized interlayer adhesion and virtually no warping. TitanX is used by industries worldwide for creating functional prototypes and end-use parts.

Key features

- Strongly improved mechanical properties

- >65% more impact resistant than regular ABS

- Minimal warping, excellent interlayer adhesion, and seamless build plate adhesion

- Precise 3D printing with remarkable fine detail

- Vicat softening temperature of 97oC

- Compatible with Helios Support for complex multi-extrusion 3D printing

- Nearly odorless processing and no unpleasant styrene smell when being 3D printed

Applications

• Functional prototyping

• End-use parts

• Fit testing

• Engineering parts

• Short-run manufacturing

General printing guidelines *

| Nozzle size: ≥ 0.15mm | Layer height: ≥ 0.1mm | Experience level: Beginner |

| Print temp: ± 240 - 265oC | Fan speed: 0-30% | |

| Heat bed: ± 70 - 100oC | Enclosure needed: Recommended |

*) Above displayed settings are meant as guidance to find your optimal print settings. These ranges in settings should work for most printers, but please do feel free to experiment outside these ranges if you think it is suitable for your printer. There are a lot of different types of printers, hot-ends and printer offset that it is extremely difficult to give an overall one-size-fits-all setting.

Filament length

| p: 1.10 g/cc | 50 gr coil | 0.75 Kg spool | 2.3 Kg spool | 4.5 Kg spool | 8 Kg spool |

| Ø 1.75mm | ± 18.9m | ± 283m | ± 869m | ± 1701m | ± 3024m |

| Ø 2.85mm | ± 7.1m | ± 107m | ± 328m | ± 641m | ± 1140m |

TitanX is an industrial-grade, high-performance and FFF/FDM-optimized ABS based engineering filament. TitanX is the evolution of ABS into a warp-free filament with unsurpassed mechanical properties and is extremely suitable for 3D printing large scale and high precision engineering objects. TitanX is truly FFF/FDM-optimized as it has zero warping, a perfect interlayer adhesion and can be printed directly on a heated glass plate without any adhesives or tapes to be used.

| Properties | Typical value | Test Method | Test condition |

|---|---|---|---|

| Physical | |||

| Specific gravity | 1.10 g/cc | ISO 1183 | - |

| Melt flow rate | 41 g/10min | ISO 1133 | 260oC/5Kg |

| Water absorption | - | - | - |

| Moisture absorption | - | - | - |

| Mechanical | |||

| Impact strength | 58 KJ/m2 | ISO 179 | Charpy Notched @23oC (73oF) |

| Tensile strength | 43.6 Mpa | ISO 527 | @Yield 50mm/min (2 inch/min) |

| Tensile modulus | 2030 Mpa | ISO 527 | 1mm/min |

| Elongation at break | 34% | ISO 527 | @ Break 50mm/min (2 inch/min) |

| Flexural strength | - | - | - |

| Flexural modulus | - | - | - |

| Hardness | - | - | - |

| Thermal | |||

| Print temperature | ± 240 - 260oC | - | - |

| Melting temperature | ± 235 ± 10oC | ISO 294 | - |

| Viscat softening temp. | ± 97oC | ISO 306 | VST/A/50 (50° C/h, 10N) |

| Optical | |||

| Haze | - | - | - |

| Transmittance | - | - | - |

| Gloss | - | - | - |