Dupa plasarea solicitării de comandă, in sectiunea Istoric puteti vedea cate solicitări de comandă mai avem de procesat inaintea dumneavoastra

Program de lucru: Luni - Vineri 9:00 - 18:00, pauza 13:00 - 14:00.

Se efectueaza lucrari de mentenanta la site si pot aparea erori. In cazul in care intampinati erori va rugam sa reincercati mai tarziu.

Ridicarea personala este disponibila pentru comenzile achitate in avans. Se pot ridica dupa ce sunt pregatite.

No products

View larger

View larger

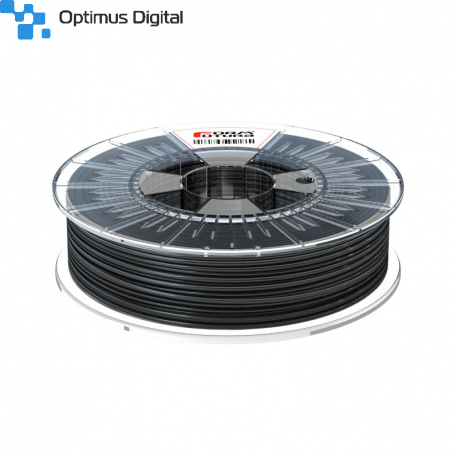

FormFutura Python Flex Filament - Black, 2.85 mm, 500 g

8718924479322

New product

Python Flex is a high-performance flexible thermoplastic polyurethane (TPU) filament, which is designed for high-speed printing on both direct drive and Bowden style extruders.

See Description for more details about the product.

Don't delay, buy today. Add to cart now!

1 Item

Warning: Last items in stock!

- Write a review

- Remove this product from my favorite's list.

- Add this product to my list of favorites.

More info

Description

Python Flex is extremely easy to print flexible filament which can be printed directly on a glass plate without having to use the heatbed. Python Flex has a shore hardness of 98A and has great elastic properties as it allows itself to be stretched up to 450% before breaking. Python Flex is extremely transparent in its natural form and has excellent resistance to oil, greases, microorganisms, and abrasion.

Unique features

- The perfect combination of strength, flexibility, and elasticity

- Designed for high-speed printing

- The flexible filament that can be printed at speeds of >80mm/s

- Heat resistant up to 138oC

- Watertight printing possible with only single wall prints

- Excellent resistance to oil, greases, microorganisms, and abrasion

- Very easy to print on both direct drive & Bowden style extruders

- Warp-free printing and no deformation after cooling

- Improved flowing behavior and inter-layer adhesion

- Good first layer adhesion to several (un)heated print surfaces

General printing guidelines *

| Nozzle size: ≥ 0.25mm | Layer height: ≥ 0.1mm | Flow rate: ± 110 - 130% |

| Print temp: ± 220 - 250oC | Print speed: Medium-Fast | Retraction: Yes ± 5mm |

| Heat bed: ± 0 - 60oC | Fan speed: 50-100% | Experience level: Intermediate |

*) Above displayed settings are meant as guidance to find your optimal print settings. These ranges in settings should work for most printers, but please do feel free to experiment outside these ranges if you think it is suitable for your printer. There are a lot of different types of printers, hot-ends, and printer offset that it is extremely difficult to give an overall one-size-fits-all setting.

*) Print temperature depends on printing speed and wall thickness (e.g. ± 220 - 230oC for single wall objects with no infill at 50mm/s and ± 245 - 255oC for high infilled objects at 100mm/s)

*) Flow rate depends on the configuration of hotend and feeder setup but is increases when printing speed increases (e.g ± 110% for 50mm/s till even 130% for 100mm/s

| ρ: 1.16 g/cc | 50 gr coil | 0.5 Kg spool |

| Ø 1.75mm | ± 17.9m | ± 179m |

| Ø 2.85mm | ± 6.8m | ± 68m |

Hygroscopy

Python Flex is a very hygroscopic material and will attract and hold water molecules from the surrounding environment. When opened and exposed to humidity too long this can have a negative effect on the printing behavior and quality of the filament. It is therefore strongly recommended to immediately remove the spool from the printer after printing and store it in a vacuum bag or airtight container without silica. When the filament is too wet it is recommended to dry Python Flex in an oven or filament drying machine at 65C. Drying time depends on how long the filament has been exposed to humidity. Python Flex is packaged in a vacuum bag with a guaranteed moisture content of less than 0.2% to ensure ideal printing behavior and results directly after opening the spool.

| Properties | Typical value | Test Method | Test condition |

|---|---|---|---|

| Physical | |||

| Specific gravity | 1.16 g/cc | ISO 1183 | - |

| Melt flow rate | - | - | - |

| Water absorption | - | - | - |

| Moisture absorption | - | - | - |

| Mechanical | |||

| Impact strength | No Break | ISO 179 | Charpy Notched @23oC (73oF) |

| Tensile strength | 50.0 Mpa | ISO 527 1/2 | @Yield |

| Tensile modulus | 150 Mpa | ISO 527 | - |

| Elongation at break | 450% | ISO 527 1/2 | - |

| Flexural strength | - | - | - |

| Flexural modulus | - | - | - |

| Hardness | 98A | ISO 7619‐1 | Shore A Hardness |

| Thermal | |||

| Print temperature | ± 220 ‐ 250oC | - | - |

| Melting temperature | ± 220 ± 10oC | - | - |

| Viscat softening temp. | ± 138oC | ASTM D1525 | B/2 (120oC/h, 50N) |

| Optical | |||

| Haze | - | - | - |

| Transmittance | - | - | - |

| Gloss | - | - | - |