Dupa plasarea solicitării de comandă, in sectiunea Istoric puteti vedea cate solicitări de comandă mai avem de procesat inaintea dumneavoastra

Program de lucru: Luni - Vineri 9:00 - 18:00, pauza 13:00 - 14:00.

Se efectueaza lucrari de mentenanta la site si pot aparea erori. In cazul in care intampinati erori va rugam sa reincercati mai tarziu.

Ridicarea personala este disponibila pentru comenzile achitate in avans. Se pot ridica dupa ce sunt pregatite.

No products

View larger

View larger

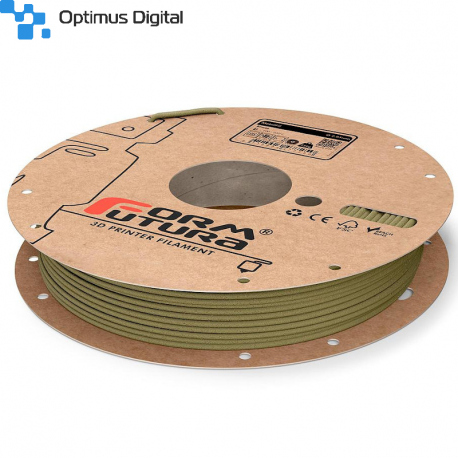

FormFutura MetalFil Filament - Brass, 2.85 mm, 750 g

8718924477250

New product

MetalFil - Brass is a metal-filled PLA-based filament with approximately 70% of gravimetric brass filling.

See Description for more details about the product.

Don't delay, buy today. Add to cart now!

1 Item

Warning: Last items in stock!

- Write a review

- Remove this product from my favorite's list.

- Add this product to my list of favorites.

More info

Description

This incredible high filling with brass powders enables every FDM 3D printer user to 3D print brass objects which are almost indistinguishable from genuine brass casted objects. MetalFil - Brass is easy to print and can be printed on full metal, PEEK, and PFTE hotends and can perfectly be printed with ≥ 0.4mm nozzles with retraction settings enabled on both direct drive extruders, as well as on Bowden style extruders, which is a truly unique feature for a metal-filled filament. MetalFil Brass printed objects are extremely easy to polish.

Unique features

- 70% filled with brass powder

- Real brass look and “cold” brass metal feel

- o More than twice as heavy compared to PLA (density of 2.78 g/cc)

- Easy to post-process

- MetalFil Brass can be brushed, sanded, polished, waxed and coated

- Very easy to print on both direct drive & Bowden style extruders

- Warp-free printing and no deformation after cooling

- Improved flowing behavior and inter-layer adhesion

- Good first layer adhesion to several (un)heated print surfaces

General printing guidelines *

| Nozzle size: ≥ 0.4mm | Layer height: ≥ 0.1mm | Flow rate: ± 104% |

| Print temp: ± 215 - 235oC * | Print Speed: Medium | Retraction: Yes ± 5mm |

| Heat bed: ± 0 - 60oC | Fan Speed: 50 - 100% | Experience level: Beginner |

*) Above displayed settings are meant as guidance to find your optimal print settings. These ranges in settings should work for most printers, but please do feel free to experiment outside these ranges if you think it is suitable for your printer. There is a lot of different type of printers, hot-ends, and printer offset that it is extremely difficult to give an overall one-size-fits-all setting.

*) If blobs/lumps form around the nozzle then your print temperature is too high.

Post-processing MetalFil - Brass

Brushing and/or sand grinding

Once printed MetalFil - Brass objects can very easily be brushed with a brass brush or sanded with fine grid sandpaper. By brushing and/or sand grinding your printed object you will brush/shine up the high concentration of brass powders

Build-in white polish feature

After being brushed and/or sanded MetalFil - Brass will reveal its white polish feature. A very thin white layer/haze on your object will now allow you to easily polish your 3D print into a beautiful brass object.

Professional polishing with a rotary tumbler

Post-processing a MetalFil - Brass 3D printed object with a rotary tumbler will make your FDM 3D printed object indistinguishable from genuine brass casted objects.

Waxing and coating

After every above mentioned post-processing measure, you can always wax or coat your printed object to get an incredible shine effect. Waxing can be done with products such as beeswax and for coating one can think about products such as XTC-3D.

Abrasiveness

Please be aware that MetalFil filaments contain a very high concentration of metal powders, which have an abrasive nature. In general, these metal powders will accelerate the nozzle-wear of brass nozzles, much faster than unfilled filaments. We recommend using nozzles from stainless steel or other hardened alloys.

Filament length

| p: 2.78 g/cc | 50 gr coil | 0.75 Kg spool |

| Ø 1.75mm | ± 7.5m | ± 112m |

| Ø 2.85mm | ± 2.8m | ± 42m |

Nozzle cleaning

When printing with filled/composite filaments it is recommended to clean your nozzle immediately after printing by feeding 15-20cm PLA filament through your nozzle. This will make sure that any potential fillers are flown out of your nozzle. It is even better to use glow in the dark PLA as the extremely hard phosphorous particles are much more likely to scrape out residual waste from your nozzle.

| Properties | Typical value | Test Method | Test condition |

|---|---|---|---|

| Physical | |||

| Specific gravity | 2.78 g/cc | ISO 1183 | - |

| Melt flow rate | - | - | - |

| Water absorption | - | - | - |

| Moisture absorption | - | - | - |

| Thermal | |||

| Print temperature | ± 180 ‐ 195oC | - | - |

| Melting temperature | ± 195 ± 10oC | ISO 294 | - |

| Viscat softening temp. | ± 65oC | ISO 306 | VST/A/50 (50oC/h, 10N) |