Dupa plasarea solicitării de comandă, in sectiunea Istoric puteti vedea cate solicitări de comandă mai avem de procesat inaintea dumneavoastra

Program de lucru: Luni - Vineri 9:00 - 18:00, pauza 13:00 - 14:00.

Se efectueaza lucrari de mentenanta la site si pot aparea erori. In cazul in care intampinati erori va rugam sa reincercati mai tarziu.

Ridicarea personala este disponibila pentru comenzile achitate in avans. Se pot ridica dupa ce sunt pregatite.

No products

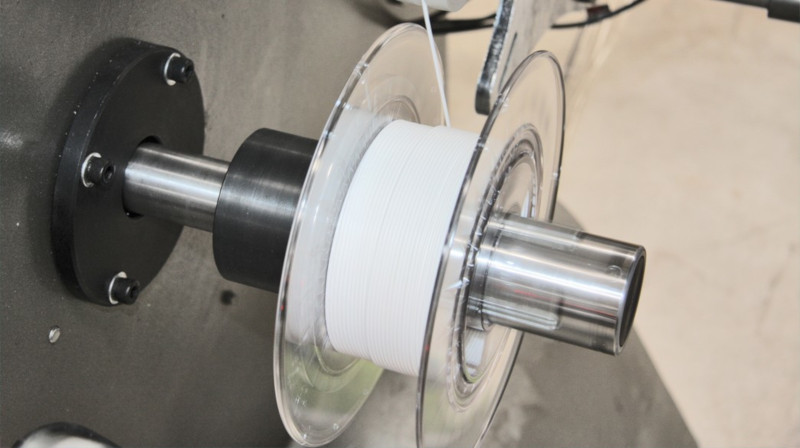

View larger

View larger

Sakata 3D Ingeo 3D850 PLA Filament - Gold 1.75 mm 500 g

1303011500

New product

- High resolution, premium filament. Easy to mold, print and engrave. High rigidity and low contraction rate.

- Recommended temp.: 190o-220oC

- Diameter variability: +/- 0.03mm

- Compatible with all FDM printers

- Heated bed temp. : not needed

- Printing speed : max 200mm/s

See description for more details about the product.

Add to cart now!

This product is no longer in stock

- Write a review

- Remove this product from my favorite's list.

- Add this product to my list of favorites.

More info

Description

SAKATA 3D PLA 850 filament is suitable for all consumer-grade 3D FDM/FFF printers. This filament exhibits fast crystallization rates and is able to develop improved heat resistance in 3D printed parts. SAKATA 3D PLA 850 filament has excellent 3D printing characteristics such as precise detail, good adhesion to build plates, less warping and curling, and low odor. Made in Spain by POLIMERSIA GLOBAL S.L

From impact resistance to a low carbon footprint, Ingeo PLA grades provide an unmatched portfolio of advantages in 3D printing filament. The specialty grades 3D850 and 3D870 were developed specifically for manufacturing 3D printer monofilament. These grades have excellent processability and printability, as well as improved impact resistance in printed parts.

Monofilaments made with Ingeo PLA have notable 3D printing characteristics such as precise detail, good adhesion to build plates (no heating needed), less warping or curling, and low odor (no strong, greasy, or oily smell while printing). These properties make this grade well-suited for 3D printing using many different types of printers and for a broad range of printing applications.

The popularity of PLA stems from the fact that it is easy to print, doesn’t cause bad odors and is environmentally friendly. However, generic PLA compositions have their cons: in broad terms, PLA compositions we most frequently find on today’s market exhibit low distortion temperatures, high friction coefficients, and a low melt flow index.

These attributes translate into a more rigid and delicate 3D print which is harder to extrude and easier to fracture. To overcome some of PLA's issues and with the objective of improving 3D printing results, NatureWorks, backed by years of experience in the polymer industry, created the PLA Ingeo 3D850 resin.

PLA 850. First and foremost, the melt flow index is higher than ABS plastic. A high melt flow index often means a lower friction coefficient. This high melt flow index thus yields an advantage because extruder motors have to do less work to extrude the same length of filament (print faster). Also, a higher melt flow index leads to a cooler extruder operating temperatures and less wear on parts. Another advantage is a lowered probability of extruder gear slippage or stripping of the filament when backpressure occurs in the hot end.

When looking at a broader range of 3D printer filaments, it’s typical to see that materials with high impact resistances have conversely low tensile strengths (or vice-versa). The chart is shown below (my3dmatter) illustrates how different filaments compare when looking at their tensile strength and impact resistance. We can see that a trade-off between tensile strength and impact resistance is apparent, and it’s rare to see filaments that exhibit both properties at the same time.

Next, let's take a closer look at 850's flexural modulus (i.e. the materials tendency to bend under stress).

So what does having a high flexural modulus mean for 3D printing?

Printing structures that are long and thin will have less deflection or bend under pressure, thus eliminating the need for supports or thick rafts.

One of the biggest issues with PLA is its low heat deflection temperature or heat distortion temperature also known as HDT. HDT is the temperature at which a polymer or plastic will deform under pressure. Historically, when printing parts requiring high resistance to temperature, ABS was the best material. Nowadays, 850's HDT is a whopping 144oC which means it will suffer minute deformation (if any) below that temperature. When compared to typical ABS and PLA having HDT values of 85oC and 50oC respectively, heat resistance is much improved.

From a usage perspective, filaments made with 3D850 resin feature other enhancements such as excellent bonding with print surfaces, a feature that is significantly improving first layer quality and minimizing the risk of warping. Next, shrinkage of parts during and after printing is also non-existent and virtually no odor is present during extrusion.

In conclusion, 850 shows that the trade-off between tensile and impact strengths can be avoided, allowing very resistant PLA prints. The PLA Super Premium Series is designed to offer tough and thermally resistant prints, analogous to ABS but without its disadvantages.

3D Printing Monofilament - High Heat Grade

Monofilament Applications

IngeoTM 3D850 is a grade developed for manufacturing 3D printer monofilament. This grade exhibits faster crystallization rates and is able to develop improved heat-resistance in 3D printed parts. This low color resin grade demonstrates the best performance in formulated systems designed to enhance toughness or heat-resistance.

Monofilaments made with Ingeo 3D850 have excellent 3D printing characteristics such as precise detail, good adhesion to build plates, less warping or curling, and low odor.

| Physical Properties | Value | Unit | ASTM Method |

|---|---|---|---|

| Specific Gravity | 1.24 | g/cc | D792 |

| MFR | 7-9 | g/10 min2 | D1238 |

| Relative Viscosity3 | 4.0 | D5225 | |

| Peak Melt Temperature, | 165-180 | oC | D3418 |

| Glass Transition Temperature | 55-60 | oC | D3418 |

1. Typical properties for injection molded bars; not to be construed as specifications.

2. 210oC/2.16 kg

3. RV measured at 1.0 g/dL in chloroform at 30oC

4. 3D printed part / 100% in-fill, annealed at 110oC/15 min

| Mechanical Properties (crystalline) | Value | Unit | ASTM Method |

|---|---|---|---|

| Tensile Yield Strength | 7,440 (51) | psi (MPa) | D638 |

| Tensile Elongation | 3.31 | % | D638 |

| Notched Izod Impact | 2.21 (118) | ft-lb/in (J/m) | D256 |

| Tensile Strength | 7,290 (50) | psi (MPa) | D638 |

| Tensile Modulus | 335,790 (2315) | psi (MPa) | D638 |

| Heat Distortion Temperature 66 psi (0.45 MPa) | 80-90 | oC | E2092 |

| Clarity Opaque | (when crystalline) | ||

Processing Information

Ingeo 3D850 polymer is available in pellet form. This grade can be used in crystalline engineered formulations where nucleants, modifiers, process aids, reinforcing agents, etc. are used to meet the requirements of the application.

Drying prior to processing is essential. The polymer is stable in the molten state, provided that the extrusion and drying procedures are followed. Post-annealing in the range of 176-266oF (80-130oC) can be used to promote crystallization and improve the heat deflection temperature of the 3D printed part.

Machine Configuration

Ingeo polymers will process on conventional extruders using general-purpose screws with L/D ratios from 24:1 to 30:1 and a compression ratio of 2.5:1 to 3:1. Smooth barrels are recommended.

| Processing Temperature Profile | ||

|---|---|---|

| Melt Temperature | 410oF | 210oC |

| Feed Throat | 113oF | 45oC |

| Feed Temperature | 355oF | 190oC |

| Compression Section | 375oF | 200oC |

| Metering Section | 390oF | 210oC |

| Adapter | 390oF | 210oC |

| Die | 390oF | 210oC |

| Screw Speed | 20-150 rpm | |

| Filament Diameter Inspection | (on-line) Essential for quality monofilament (+/- 3% max. deviation) |

|

| 3D Printing Temperature | 190-230oC | |

| Annealing Temperature | 80-130oC | |

| Print Bed Temperature | None needed. (or 50-70oC if applicable) | |

Don't delay, buy today.

Add to cart now!

Reviews

Customers who bought this product also bought:

-

Power Button...

Power Button with White LED See description...

$1.86

-

Devil Design...

Filament PLA - thermoplastic polyester in the...

$22.80

-

3 x 4 x 2 mm...

3 x 4 x 2 mm SMD Button See description for...

$0.07

-

Filament...

Filament Feeder Gear for 3D Printer

$1.00

-

Sakata 3D...

High resolution, premium filament. Easy to...

$13.20

-

Devil Design...

Filament PLA - thermoplastic polyester in the...

$22.80

-

Sakata 3D...

High resolution, premium filament. Easy to...

$13.20

-

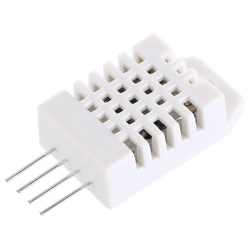

DHT22...

DH22 is a high performance temperature and...

$5.52

-

SG90 Micro...

This mini servo motor is designed for radio...

$3.36

-

High Power...

High Power PWM Switch Module (5 - 36 V, 15 A)...

$1.56