Dupa plasarea solicitării de comandă, in sectiunea Istoric puteti vedea cate solicitări de comandă mai avem de procesat inaintea dumneavoastra

Program de lucru: Luni - Vineri 9:00 - 18:00, pauza 13:00 - 14:00.

Se efectueaza lucrari de mentenanta la site si pot aparea erori. In cazul in care intampinati erori va rugam sa reincercati mai tarziu.

Ridicarea personala este disponibila pentru comenzile achitate in avans. Se pot ridica dupa ce sunt pregatite.

No products

View larger

View larger

HT ColorFabb White 1.75 mm 700 g

8719033555419

New product

This is not an off-white color, but the most intense white we could achieve.

See description for more details about the product.

Add to cart now!

1 Item

Warning: Last items in stock!

- Write a review

- Remove this product from my favorite's list.

- Add this product to my list of favorites.

More info

Description

colorFabb has teamed up with Eastman Chemical Company to develop co-polyester based materials for FFF/FDM 3D printing. Now you can fulfill your vision with 3D creations that exhibit sparkling clarity and gloss and superior toughness. With superior melt strength and dimensional stability, Amphora delivers advanced bridging capabilities to create stronger and more detailed items - with low odor and low emissions.

Eastman Amphora™ 3D polymer is a low-odor, styrene-free choice that is uniquely suited for 3D printing applications. With Amphora, items can be created that are more functional, more durable, more efficient, and attractive.

colorFabb_HT is made with Amphora HT5300 and is a low-odor and styrene-free material uniquely suited for advanced 3D printing users, particularly those who need their models to exhibit excellent durability, toughness and high-temperature resistance with a Tg of over 100⁰C. colorFabb_HT empowers professional users to create more durable and useful items, making prototyping truly functional.

colorFabb_HT is enabled by Eastman Tritan™ copolyester technology

colorFabb_HT

Heat resistance 100C | FDA compliance | Styrene-free | BPA-free

High-temperature resistance

One of ColorFabb_HT’s biggest asset is its elevated heat resistance temperature of 100C. That means your co-polyester creations can finally withstand heat without deforming. This opens up new areas in which 3D printed applications can be successfully applied.

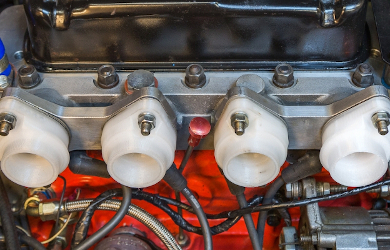

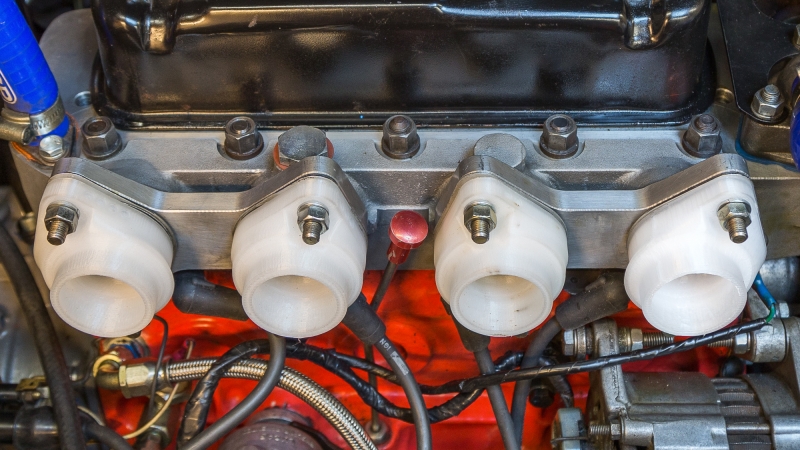

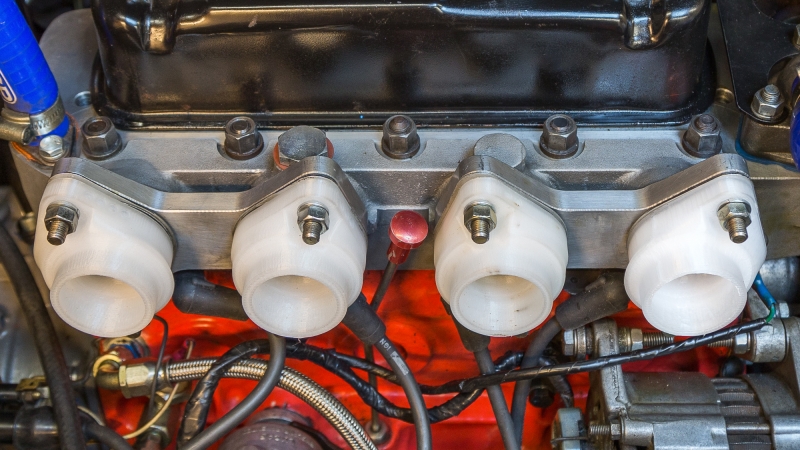

By using colorFabb_HT, Dennis is able to experiment with custom shaped inlet manifolds to improve the performance of this Mini track car. The fact that he can now test these parts on a running engine means a lot in his design process. More information on this project soon!

Tough material = tough parts

colorFabb_HT is enabled by Eastman Tritan™ copolyester technology

ColorFabb_HT is uniquely suited for advanced 3D printing users, particularly those who need their creations to exhibit excellent durability, toughness and temperature resistance.

What is colorFabb_HT?

ColorFabb_HT is a low-odor and styrene-free material uniquely suited for advanced 3D printing users, particularly those who need their models to exhibit excellent durability, toughness, and high-temperature resistance.

ColorFabb_HT empowers professional users to create more durable and useful items, making prototyping truly functional. ColorFabb_HT is made with BPA-free Eastman Amphoratm HT5300 3D polymer.

colorFabb_HT is enabled by Eastman Tritan™ copolyester technology

Which co-polyester should you choose?

You might have noticed that colorFabb now offers 3 types of co-polyesters, each with different material characteristics. In case you’re wondering which material will suit your application keep on reading to find out more.

Apart from having their differences, they also share some great characteristics. All materials feature good chemical resistance, styrene-free & BPA-free 3D printing and FDA food contact compliance.

colorFabb nGen – All-round

nGen is a great all-round material, meaning it’ll do the job for most day to day 3D printing jobs. It features an elevated temperature resistance of 85C and comes in a great variety of 17 colors. This makes nGen very suitable for visual prototyping and moderate functional prototyping. Processability is great due to the high-flow nature of the material, which makes it suitable for beginners who just started out. Also, advanced users will find the nGen material.

colorFabb_XT – Tough

For those users looking to 3D print functional parts that need better toughness than your standard PLA based prints and better temperature resistance, colorFabb_XT is the material of choice. The material is processed at temperatures ranging from 240C to 260C combined with a high melt strength makes the material less suited for beginners.

colorFabb_HT – Temperature resistance

Tougher then _XT and better temperature resistant, however not as easy to process. Therefore this material is directed at advanced users, who specifically need the temperature resistance and best toughness available.

To master the _HT material users should fine-tune the first layer settings in order to prevent warping of printed parts. We advise 110/120C bed temperatures, in some cases combined with adhesion tools such as BuildTak.

| COLORFABB NGEN | COLORFABB_XT | COLORFABB_HT | |

|---|---|---|---|

| Processing temperature | 220°C/240°C | 240°C/260°C | 250°C/280°C |

| Heated buildplate | 75°C/85°C | 5°C/75°C | 100°C/110°C |

| Temperature resistance | 85°C | 75 °C | 100°C |

| Processing window | +++ | + | + |

| Printing speed | +++ | + | + |

| Toughness | + | ++ | +++ |

Why colorFabb_HT?

What if your needs go beyond 3D printing visual models and the occasional demonstrator. What if your parts need to perform in real-world situations and need to exhibit excellent durability?

ColorFabb_HT is made for advanced professional users who have very specific needs in terms of temperature resistance and material toughness.

ColorFabb_HT offers the best mechanical performance of all co-polyester filaments in our portfolio and features the highest temperature resistance of 100°C.

Automotive

colorFabb_HT unique combination of high toughness and temperature resistance makes this material suited for real-world applications in industries such as automotive.

Whether it’s printing parts used in the engine bay or functional brackets and other clamps _HT will do the trick. Since it’s a durable material mechanical properties will remain over time.

Functional prototyping

We expect many more applications to be developed in this area. Whether it’s a headphone or housing for holding electronics parts the material needs good stability and decent heat resistance. Of course, colors are important too, especially when these electronics are custom made to your liking.

Durable parts

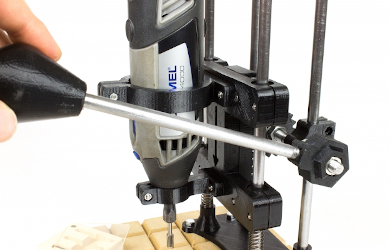

Because of its durable nature, the material is an excellent choice for making your own tools and clamps. Whether it’s an improvement for your workshop or actual custom made parts for a production line, this material will be uniquely suited for the job.

How to print with colorFabb_HT?

To get the best possible quality out of any 3D printing material it’s important to match the slicer settings with the material which is used. On this page, we’ll run through the most important settings and suggest good starting values for various printers. If your machine isn’t in our list use the general recommended settings.

In the table below you can quickly find values for your machine, scroll a bit further down to read more about each setting.

PRINT SETTINGS FOR COLORFABB_HT

| ULTIMAKER 2 (CURA) | ULTIMAKER 2+ (CURA) | MP PHARAOH ED (SIMPLIFY3D) | LULZBOT MINI (CURA) | STACKER (SIMPLIFY3D) | |

|---|---|---|---|---|---|

| print temperature | 250°C/260°C | 260°C | 260°C/270°C | 250°C/260°C | 265°C/275°C |

| build platform temperature | 110°C/120°C | 110°C/120°C | 110°C | 90°C (PEI SHEET) | 105°C (BuildTak) |

| print speed | 30/40mm/s | 30/40 mm/s | 40 mm/s | 30/45 mm/s | 50 mm/s |

| cooling | 0/30% | 0/30% | 0/30% | 0/30% | 0/30% |

| retraction – speed | 40 mm/s | 40 mm/s | 45 mm/s | 10/25 mm/s | 60 mm/s |

| retraction – length | 4.5 mm | 4.5 mm | 3.2 mm | 1.0/2.0 mm | 3.6/4.0 mm |

| bridge – speed | n.a. | n.a. | 50/80% | n.a. | 50% |

| bridge – cooling | n.a. | n.a. | 100% | n.a. | 100% |

| bridge – flow | n.a. | n.a. | 110% | n.a. | 110%/120% |

Heated platform

ColorFabb_HT is best printed with a heated build plate to preven medium to large sized objects from warping at the bottom layer. You don’t need to worry about layer delamination due to warping, but only about making sure the first layer stays nice and flat.

For printers with glass-plate as build surface, we recommend high temperatures of 110/120C. For most small to medium-sized part, this should be sufficient.

For bigger parts with a larger flat surface touching the buildplate you might need more adhesion to keep the part from warping. In this case, BuildTak plate can help prevent warping.

Printing temperature

The temperature we set when starting a print really depends on the chosen layerheight and print speed.

Flow of material in mm3/s = (layerheight*nozzle width)*print speed

When considering normal settings such as 0.2mm layer height and 50 mm/s speed we recommend for most machines a processing temperature of 260/280C.

At 0.1mm and 50mm/s temperature might be lower towards 250/270C.

Make sure your machine can reliably work at these elevated temperatures, not all 3D printers are able to go beyond 250°C / 260°C.

Cooling

In order to get best possible strength from colorFabb_HT we recommend printing without cooling whenever the model geometry allows for this. If your model doesn’t feature overhanging surfaces or fine positive features (pointy bits) then it’s likely your model will print fine without cooling.

This will result in better layer adhesion, but also fewer issues with the warping of the material.

We also like the option of only activating layer cooling for the perimeter lines, the infill is not cooled and therefore should maintain the best possible layer adhesion.

Bridging

Most slicers will allow users to set special settings when a bridge is printed in a model. Usually we can set bridging speed, bridging cooling and sometimes also bridging perimeter width (or flow).

We recommend slower printing on bridges since there’s no material to support the printed line we don’t want to ‘break the melt’ by moving too fast. Slowing down the speed when bridging helps retain the melt strength and also allows the printed line to cool down in mid-air.

Cooling can be set at 100% to help the cooldown of the first printed lines.

If you can still see the melt break when printing a bridge, try and increase the flow or bridge perimeter width.

Cooling

When printing colorFabb_HT we recommend 0% cooling whenever the model geometry allows for this. If your model doesn’t feature overhanging surfaces or fine positive features (pointy bits) then you should be able to print the model fine without cooling. Don’t forget to adjust the minimal layertime, around 8/10 seconds should be fine.

This will result in parts with optimal layer adhesion and also less chance of warping of the parts

Retraction

Before you start tweaking the retraction values make sure you’ve found the sweet spot in terms of printing temperature and speed for your machine.

PLA retraction values should be a good starting value for most machines. One can expect slightly higher values of retraction speed and retraction length. For more specific values have a look at our table above.

Coasting is a nice option included in Simplify3D. This is the act of stopping the extrusion just before a travel move is triggered, this helps get rid of the pressure in the hot-end and therefore also making a retraction move more effective

Minimal layer time

If you’re familiar with the minimal layer time setting then you’ll know this is what causes a printer to slow down when printing fine features on a model. Slowing down the print allows each layer to cool down a minimum amount of time. This is of course different for each material, because it depends on how fast a material can dissipate heat and how much heat needs to be dissipated.

For colorFabb_HT it’s also important to adjust the minimum layer time when you want to print without cooling for best layer adhesion.

Don't delay. Buy today.

Add to cart now!

Reviews

Customers who bought this product also bought:

-

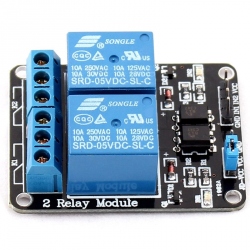

5 V Relay...

This module allows you to control high voltage...

$1.88

-

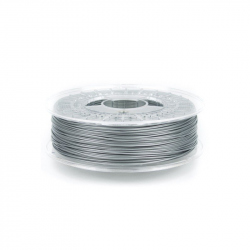

ColorFabb XT...

Color is important for most 3d printing...

$24.00

-

ColorFabb...

How about printing those robot parts with this...

$24.72

-

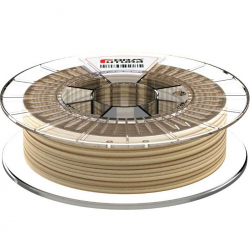

FormFutura...

EasyWood is a wood-filled PLA-based filament...

$44.68

-

0805 SMD...

0805 SMD chip resistors with 5% precision for...

$4.80

-

Corner...

Corner Connector Bracket for 20x20 mm Profiles

$0.72

-

Case for...

Case for Power Bank - White See description...

$2.16

-

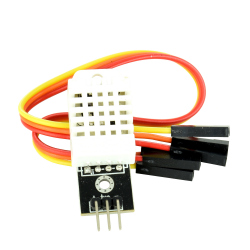

DHT22...

size: 28 mm x width 12 mm x height 10 mm...

$5.55

-

Neodymium...

Neodymium Block Magnet 5x5x1 Thick N38 See...

$0.21

-

Raspberry Pi...

Genuine Product The latest series of...

$72.58