Dupa plasarea solicitării de comandă, in sectiunea Istoric puteti vedea cate solicitări de comandă mai avem de procesat inaintea dumneavoastra

Program de lucru: Luni - Vineri 9:00 - 18:00, pauza 13:00 - 14:00.

Se efectueaza lucrari de mentenanta la site si pot aparea erori. In cazul in care intampinati erori va rugam sa reincercati mai tarziu.

Ridicarea personala este disponibila pentru comenzile achitate in avans. Se pot ridica dupa ce sunt pregatite.

No products

View larger

View larger

FormFutura AquaSolve PVA Filament - Natural, 2.85 mm, 50 g

8718924473627

New product

AquaSolve PVA (polyvinyl alcohol) is a water-soluble support material for complex multi-extrusion 3D printing. AquaSolve PVA is a 3D printer filament with good thermal stability and can be 3D printed at relatively low temperatures.

See Description for more details about the product.

Don't delay, buy today. Add to cart now!

This product is no longer in stock

- Write a review

- Remove this product from my favorite's list.

- Add this product to my list of favorites.

More info

Description

AquaSolve PVA (polyvinyl alcohol) is a water-soluble support material for complex multi-extrusion 3D printing. AquaSolve PVA is a 3D printer filament with good thermal stability and can be 3D printed at relatively low temperatures. This makes AquaSolve PVA an ideal support material for PLA-based materials with good thermal and chemical adherence.

Key features

• Excellent (cold) water solubility

• Good thermal stability, resulting in less risk on deterioration/crystalizing inside the nozzle

• Max thermal stability of 210oC, tested up to 256 seconds with no flow

• Biodegradable once dissolved in water

• Safe dissolution in tap water

• Can be disposed of in the kitchen sink as the material is "ok biodegradable water" certified

• Good bonding to PLA-based materials and other (Thermo)plastics that print within a similar temperature range

Applications

• Reliable multi-extrusion 3D printing of complex structures that require a water-soluble support material

• 3D printing geometries with large overhangs, or complex hollow structures

• PVA Molds

General printing guidelines *

| Nozzle size: ≥ 0.15mm | Layer height: ≥ 0.1mm | Experience level: Expert |

| Print temp: ± 190 - 210oC * | Fan speed: 0 - 30% | |

| Heat bed: ± 0 - 60oC | Enclosure needed: No |

* Above displayed settings are meant as guidance to find your optimal print settings. These ranges in settings should work for most printers, but please do feel free to experiment outside these ranges if you think it is suitable for your printer. There are a lot of different type of printers, hot-ends, and printer offset that it is extremely difficult to give an overall one-size-fits-all setting.

* Do not exceed a printing temperature of 225oC, because AquaSolve PVA will then crystallize to quickly and it will no longer flow and/or dissolve in water. Printing with PVA materials does require a certain level of 3D printing expertise as PVA cannot stay too long in the hot secondary/support nozzle and needs to flow and by that needs expert tweaking to find the optimal "waiting temperature" for the material not to deteriorate/crystalizing in the hot secondary/support nozzle when not being 3D printed.

Filament length

| ρ: 1.23 g/cc | 50 gr coil | 0.3 Kg spool |

| Ø 1.75mm | ± 16.9m | ± 101m |

| Ø 2.85mm | ± 6.4m | ± 38m |

PVA compatibility overview *

|

AquaSolve PVA |

Atlas Support |

Helios Support |

|

|

ABSpro |

- |

- |

+ |

|

ABSpro Flame Retardant |

- |

- |

+ |

|

ApolloX |

- |

- |

++ |

|

CarbonFil |

- |

++ |

- |

|

Centaur PP |

No data |

No data |

No data |

|

ClearScent ABS |

- |

- |

++ |

|

Crystal Flex |

- |

- |

+ |

|

EasyCork |

+ |

+/- |

- |

|

EasyFil ABS |

- |

- |

++ |

|

EasyFil HIPS |

- |

- |

++ |

|

EasyFil PLA |

++ |

+ |

- |

|

EasyWood |

++ |

+ |

- |

|

FlexiFil |

No data |

No data |

No data |

|

Galaxy PLA |

++ |

+ |

- |

|

HDglass |

- |

++ |

- |

|

LimoSolve |

- |

- |

++ |

|

MagicFil Thermo PLA |

++ |

+ |

- |

|

Matt PLA |

++ |

+ |

- |

|

MetalFil |

No data |

No data |

No data |

|

Pegasus PP Ultralight |

No data |

No data |

No data |

|

Premium ABS |

- |

- |

++ |

|

Premium PLA |

++ |

+ |

- |

|

Python Flex |

- |

- |

++ |

|

ReForm - rPET |

- |

++ |

- |

|

ReForm - rPLA |

++ |

+ |

- |

|

ReForm - rTitan |

- |

- |

++ |

|

Silk Gloss PLA |

++ |

+ |

- |

|

StoneFil |

+ |

+/- |

- |

|

STYX-12 |

No data |

No data |

No data |

|

Thibra3D SKULPT |

No data |

No data |

No data |

|

TitanX |

- |

- |

++ |

|

Volcano PLA |

+ |

- |

++ |

* Above PVA compatibility overview is meant to give guidance on which of our PVA based support materials - AquaSolve PVA, Atlas Support, and Helios Support - is advised as support material in combination with various Formfutura filaments that can be used as a primary building material.

* Please do note that the above-shown PVA compatibility overview is purely meant as general guidance and advice based on our in-house expertise and experience and that it is not to be seen as a fixed principle or rule. There are numerous factors that determine the best fitting PVA support with primary building materials and it actually varies per 3D printer. Below overview can, according to our current state of knowledge, be used as guidance for the vast majority of 3D printers.

General guidance for printing with PVA support materials

Printing with PVA, in general, isn’t plug and play and does require a fair amount of 3D printing expertise as there isn’t a generic one-size-fits-all setting for dual extrusion printing with PVA materials. The optimal PVA settings can even vary between the same models of 3D printers.

One of the most common challenges are to establish a good bond between the PVA support material and the primary building material. Below parameters are of utmost importance to establish good adherence.

• Verify the extrusion distance between the printed object and the PVA support.

• The default setting in most slicer software is often set at a distance of 0.1mm or 0.2mm, which works well for break-away support, but not for PVA support.

• For PVA support materials the extrusion distance must be set to 0.0mm as both materials must really come into contact with each other.

• The printing (nozzle) temperature is extremely important and it is advised to measure the actual temperature of the nozzle and to compare this temperature with the temperature set in the print settings.

• If the actual temperature of the nozzle is for instance 10oC lower than the temperature in the print settings it might very well be that the layer of PVA support material is not flowing optimally into the layer of the primary building material. It is often seen that the actual nozzle temperature varies from the print temperature set in the slicing software.

• Verify if the nozzles of your printer are properly leveled and have exactly the same height so that there is no "height difference" when layering the PVA support material on top of the primary building material.

• In order to verify this it is recommended to 3D print a 5cm x 1cm rod and to print every 1 to 2 layers with the left nozzle and the following 1 to 2 layers with the right nozzle and to repeat this process multiple times. If you notice a non-perfect layering then the nozzles aren’t properly leveled. This process can be done with PLA for instance.

Product export information

| HS Code: 39169090 | Description: Monofilament | Country of origin: the Netherlands |

Compliance *

This filament is compliant with the below-listed directives and regulations.

• RoHS directive 2011/65/EC

• REACH directive 1907/2006/EC

* This declaration of conformity to directives and regulations is prepared according to our present standard of knowledge and may be amended if new cognitions are available and applies only for the above-described products.

Don't delay, buy today.

Add to cart now!

Reviews

Customers who bought this product also bought:

-

10 cm 40p...

Ideal wires for making connections between...

$1.68

-

Optical...

Optical Limit Switch See description for more...

$0.97

-

M2 M2.5 M3...

M2 M2.5 M3 M4 Mini Nut Tool

$0.84

-

10 cm 40p...

Ideal wires for making connections between...

$1.20

-

2GT-6-610 mm...

This 2GT-6-610 mm closed belt is made of black...

$6.96

-

2GT-20 Gear...

This 20-tooth type of pulley made of aluminum...

$2.40

-

1.75 mm, 1...

You can easily print with this PLA filament and...

$16.80

-

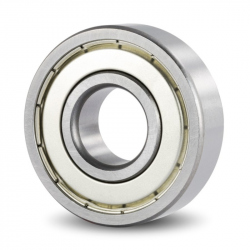

688ZZ...

688ZZ Bearing (8 x 16 x 5 mm)

$0.42

-

Mini Air...

Mini Air Pump (4.5 V)

$4.80

-

M4 Self...

Nylon-insert lock nut, polymer-insert lock nut,...

$0.06